Flat Pack Kit Technology

MODERN COLD’s kit manufacturing is the result of our R&D and engineering work and facilities. The Assembly process is quickly performed by Kit Technology. Panels finishes used in the interior and exterior surfaces are warranted against rust and corrosion. MCI manufactures Reliable and high-quality insulated refrigerated vehicle bodies with a choice of panel finishes and a wide range of accessories. Being market leader in providing holistic cold chain logistics solution to its clients while offering completely integrated capabilities. MCI truck bodies have a unique and good appearance with their flat surface, door frames of Aluminum finishes, quality accessories, corners/edges of vehicle body are protected using specially extruded aluminum profiles & the polyurethane technology is applied under pressure has a self-adhesive property. The reefer bodies are built in accordance with international standards and are designed to be operated with leading brands of cooling units. Experiencing the power of stored cooling logistics, our aim has always been to provide innovative and high-quality products and services that meet our customer’s needs.

Advantages of MODERN COLD’S Flat Pack Kit:

Light weight/ quick mounting / economical / variety of options / strength/ short delivery time/ standard packing.

Basic standard features of modern cold’s flat pack kit technology:

Panels

All our panels front wall, side walls, ceiling & flooring panels are made of single piece. Both sides of MCI Insulated panels are covered with protective film to protect the panels from scratches. The Protective Film should only be removed after the panels are installed in order to ensure maximum protection.

Maximum Insulation

Insulated panels are manufactured to international standards to ensure maximum insulation.

Choice of panel finishes

PPGI, Fiber sheets (GRP), Stainless steel, Aluminum.

Choice of Truck Bed Flooring finishes

Heavy duty Aluminum chequered sheet, Aluminum “T” flooring profiles, locally applied fiber glass finishes on top Supported By Marine plywood.

Heat Insulation

The thick polyurethane foam panels offer superior thermal insulation and the airtight sealed panel’s assembly prevents any cold air loss. Our bodies are fully equipped with a layer of insulating material responsible for limiting heat transfer that would take place between the inner & outer surfaces. PVC(Polar grade) curtains on rear & side door prevents cooling air leakage from the inner ambient.

Wide range of Accessories

Heavy duty Locking system, Meat Hanging systems, Movable & Fixed Partition with thermostat & fans, Cargo tying system, Different types of Shelves.

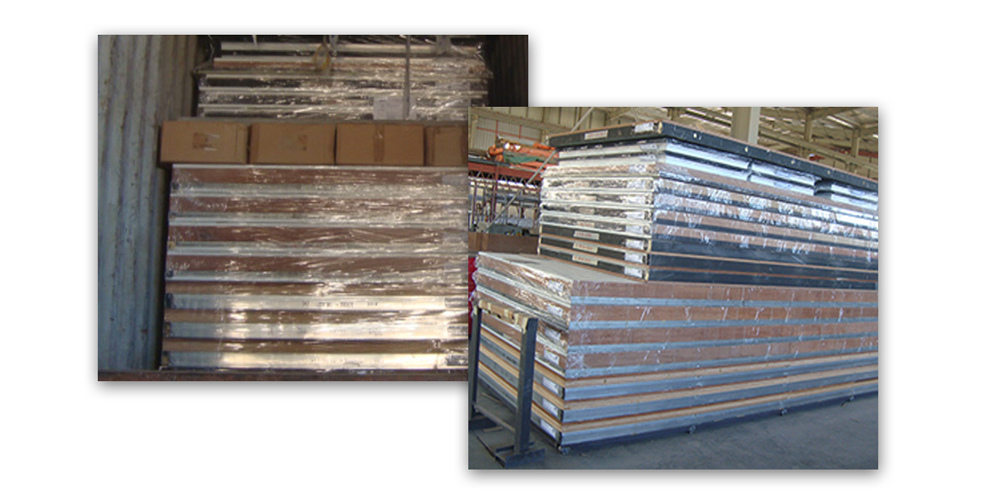

Handling, Transportation and Storage:

Insulated panels are stacked together in bundle, Plastic Covering all sides of the stack, Insulated panels are stacked both horizontally and vertically to achieve optimum container space usage. The Protective film could remain on the Insulated panels for a shortage period. However, for long period of storage it should be stored indoor.

Product Applications:

Chiller structure units with 100mm thick insulation ranging from 2.5mtr to 10mtr (truck mounted) & 6mtr to 16mtr (trailer mounted) suitable for Dairy, Flowers, Vegetable, Fruits & Chiller products.

Freezer structure units with 100mm & 150mm thick insulation ranging from 2.5mtr to 10mtr (truck mounted & 6mtr to 16mtr (trailer mounted) suitable for Meat, Poultry, Fish, Ice Cream & Frozen items.

Options:

- Single or Double side door.

- Aluminum / Stainless steel shelves custom made.

- Ladder – Foldable / pull out / step.

- Roof access ladder / wind deflector.

- Any other need of customer which can be fabricated by us.